Five-axis five-linkage mold machining center

This equipment is specially used for metal processing and woodworking tool manufacturing

Classification:

Gezi Intelligence

Five-axis five-linkage mold

Contact Us

Product Description

Equipment Introduction

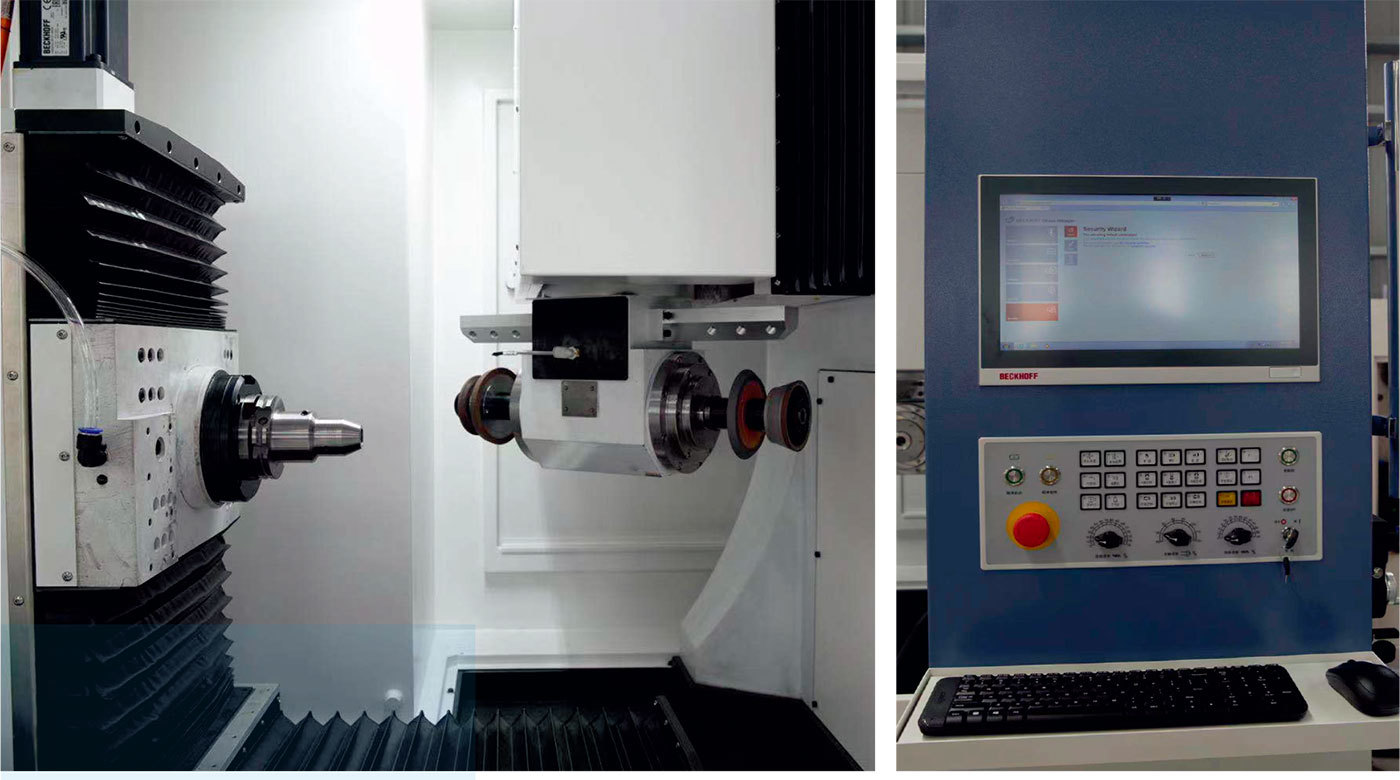

This equipment is specially used for metal processing and woodworking tool manufacturing, tool wear after grinding processing. It can process and manufacture rotary tools (drill bits, milling cutters, dumpling cutters, etc.) with a diameter of 1mm ~ 20mm and a length of 180mm for full grinding pins, or process non-standard special-shaped blades.

The equipment base adopts marble base, which has good shock resistance and stable performance. The main body of the equipment is equipped with high rigid castings. Through finite element analysis, a reasonable mechanism layout is obtained, and the secondary aging treatment of castings is adopted to greatly reduce the aging deformation of cast iron parts and ensure the stability of the basic accuracy of the equipment. The host CNC adopts the German Beifu 5-axis 5-linkage numerical control system, which consists of 3-axis (X, Y, Z) rotating shafts and 2-axis (A, C), and is equipped with double-head electric spindles. All linear shaft adopts Japan THK high precision screw THK high precision guide rail, high precision and reliable operation. The rotating shaft adopts permanent magnet synchronous torque motor Renishaw high-precision circular grating, with high rotation accuracy and no rotation gap.

|

|

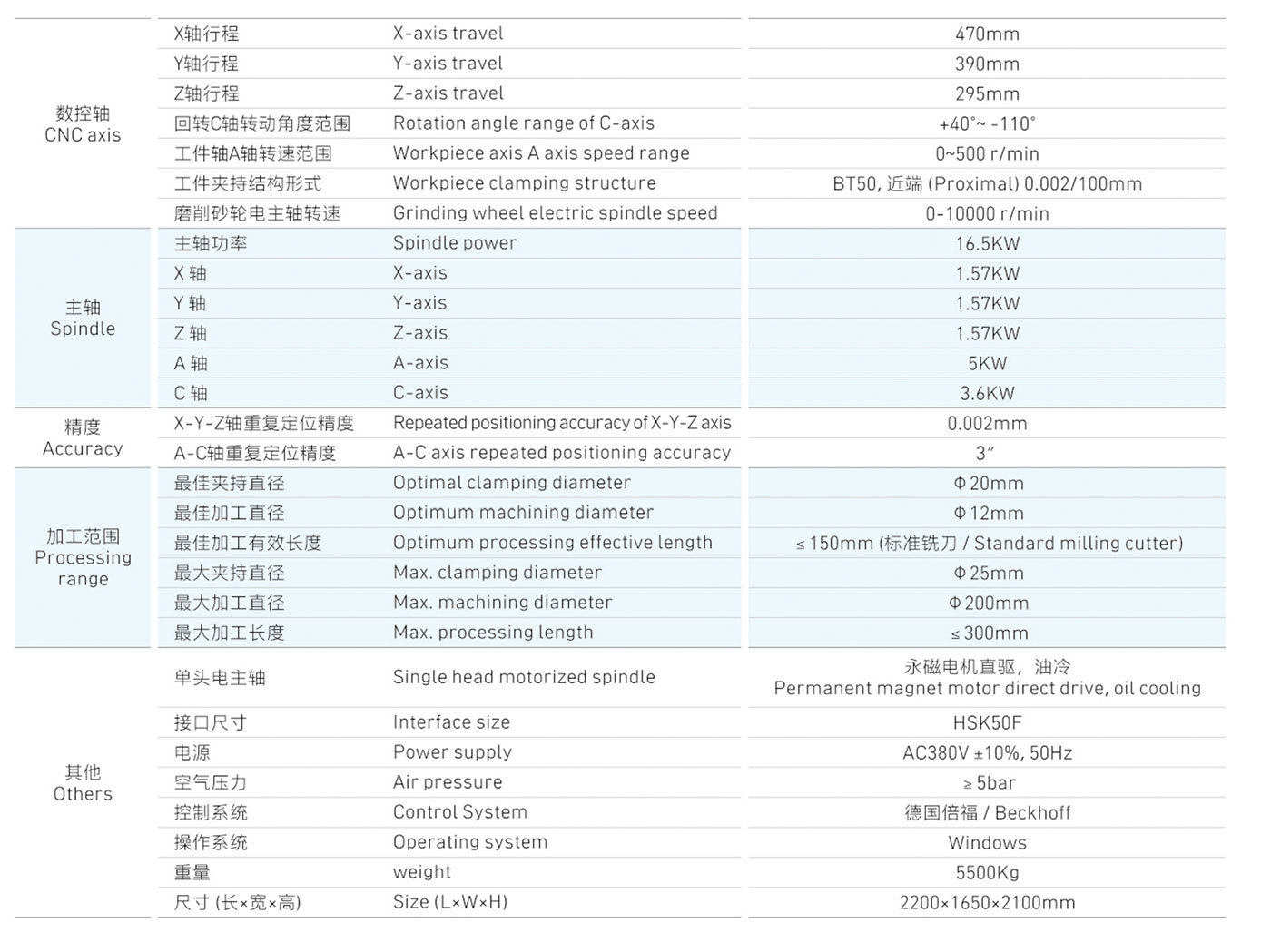

Technical Specifications

- X stroke 470mm; The screw rod and guide rail adopt European famous brands.

- Y stroke 390mm; screw rod and guide rail adopt European famous brands

- Z stroke 295mm; screw rod and guide rail adopt European famous brands

Processing range: maximum processing length 400mm; processing maximum diameter 250mm, processing minimum diameter 1mm.

Positioning accuracy 0.003mm, repeat positioning accuracy 0.002mm

Working head accuracy: axial movement: 0.001mm; Radial runout: 0.003mm mm; Radial runout after workpiece clamping: 0.003mm- 0.006mm

X-Y-Z shaft encoder resolution 0.001mm,

A, c-axis circular grating resolution: 0.001, a-axis: 360 "rotatable, c-axis -40~290

Spindle power: rated power 11.6Kw, rated torque 13Nm.

- 1. The equipment base adopts marble base, which has good seismic and stable performance.

- 2. The main body of the equipment is equipped with high rigid castings. The reasonable layout of the mechanism is obtained through finite element analysis, and the secondary aging treatment of castings is used to greatly reduce the aging deformation of cast iron parts and ensure the stability of the basic accuracy of the equipment.

- 3. The host adopts German Beifu 5-axis 5-linkage numerical control system, which consists of 3-axis (X, Y, Z) of linear axis and 2-axis (A, C) of rotary axis, and is equipped with double-headed electric spindle.

- 4. All linear shaft adopts Japan THK high precision screw THK high precision guide rail, high precision, stable and reliable.

- 5. The whole machine adopts SKF bearing imported from Sweden, which has high precision, high speed, low friction, low noise and stable operation.

- 6. The rotating shaft adopts permanent magnet synchronous torque motor Renishaw high-precision circular grating, with high rotation accuracy and no rotation gap.

Prev